Open Systems in Automation are more than a hype. Since the early 80s we have seen a lot of activities to define Open Systems for Automation. The first major project was the MAP project initialized by General Motors: Manufacturing Automation Protocols. One of the crucial standards developed in this context was MMS: Manufacturing Message Specification (ISO 9506).

When people were struggling with the implementation of 7-Layer or 3-Layer solutions including MMS some other groups believed that Fieldbusses would be the better approach. The standardization of fieldbusses come up with tens (or even tons) of different solutions under one IEC standard series: IEC 61158 with 50+ solutions.

How to build Open Systems in Automation based on this many solution? There are too many islands of very specific open systems based on special fieldbus solutions. This was one of the real reasons why people developed OPC to bridge the gap between these many islands. OPC has helped to share information between islands.

There was another issue that causes increasingly headaches: the System Configuration and Engineering. How to solve this challenge? The next wave was to standardize incompatible “integration” support solutions: FDT (Field Device Tool), EDD (Electronic Device Description) or FDI (Field Device Integration). So: What now?

Endress+Hauser has started recently a very interesting approach:

Open Integration Partner program for practical testing of multi-vendor automation topologies

The focus is on Hart, Profibus, Foundation Fieldbus, Ethernet/IP, and Profinet, as well as on FDT, EDD or FDI.

What are they proposing: “Open Integration validates the interplay of all products in a reference topology by mutual integration tests.” in a permanent lab environment.

Click HERE for a brief description in English.

Click HERE for a brief description in German.

That means: To run a comprehensive permanent “LAT” (Lab Acceptance Tests). This is something prior to “FAT” (Factory Acceptance Tests) and “SAT” (Site Acceptance Tests). Vendors involved are: Endress+Hauser, Auma Riester, Hima Paul Hildebrandt, Honeywell Process Solutions, Mitsubishi Electric, Pepperl+Fuchs, Rockwell Automation, R. Stahl und Schneider Electric.

What about “Open Systems” and IEC 61850? The power industry has understood that Interoperation Tests are very crucial to improve the standards and products. Several IOPs (Interoperability tests) – or better “LAT” (Lab Acceptance tests) – have been conducted. The last one in October 2015 in Brussels.

I hope that some companies and organizations in the Power Industry will also implement such permanently available “LAT” (Lab Acceptance Tests) that would offer 24x7 support services to the power industry.

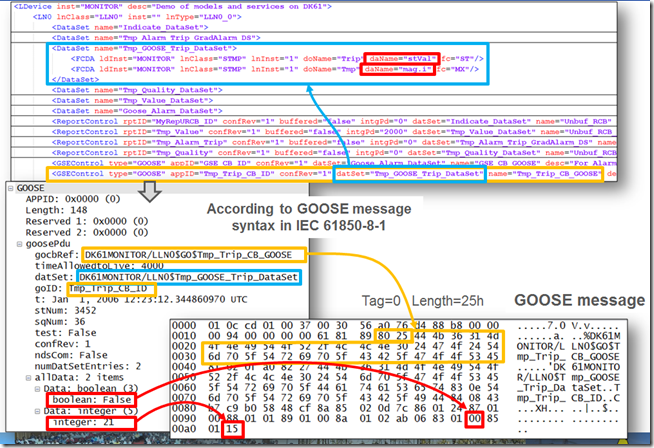

The challenges in the power industry are lower than in the industrial automation: Because we have (luckily) a single standard series that comprises:

- Device communication (real-time and SCADA protocols)

- Device Information Models (e.g. MMXU for electrical measurements)

- System Configuration Language (SCL) for engineering of Systems, Models, Device, Communication … and their Configuration

In case you would be interested to join such an effort related to IEC 61850, IEC 61400-25, and IEC 60870-5-104, let us know:

Contact us if you have something to contribute.