Ok! Hm!?

What do you think about these assumptions? 250 EVs charging in the first hour!?

As an engineer I am wondering that experts come up with such examples. First of all, I do not expect that 50 per cent of the car owners will buy an electric car in the next years. Even if they would do, why do 250 car drivers want to charge at the companies car park in the morning when they arrive?

He concludes that "we engineers have not yet thought through to the end".

I guess a lot of engineers have thought through to the end - but not many engineers or politicians are listening!

Click HERE for the report "Netzstabilität braucht Digitalisierung und Automatisierung" in the vdi nachrichten (German).

These discussions remind me of the situation in the early 80s when we had the discussion on CSMA/CD (Ethernet, IEEE 802.3) versus Token Passing (IEEE 802.4). Under the assumption that we have a shower of messages to be sent by all attached devices at the same time, we found that Ethernet could not efficiently manage the communication due to many collisions. Token Passing was understood to manage such a situation very well. Ok.

Another assumption, high load from one device only, could easily be managed by CSMA/CD - but Token Passing would end up in very low throughput ... many other assumptions could be made.

So, what is the realistic assumption for communication? Nobody knows - it all depends.

Finally Switched Ethernet (a major new development) solved the collision problem ... and Token Passing more or less became obsolete in the automation world.

In the energy domain we need first to find the future new mix of power generation and how to store, transmit, distribute, and use the power - then we can think about automation and communication. The most crucial issue may be: Who is paying for all the changes?

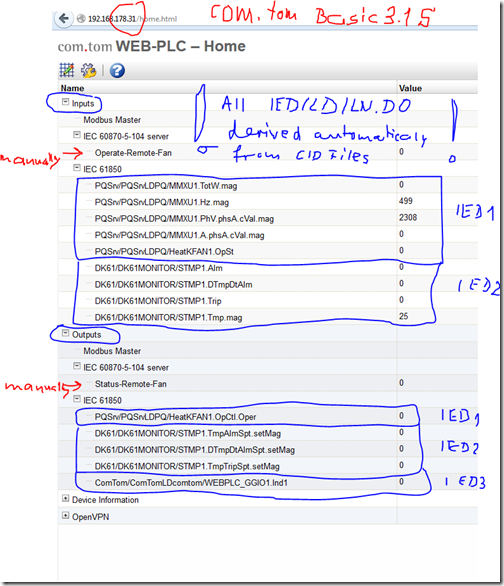

By the way: We (many engineers) know how to communicate: IEC 61850 is one of the most crucial solution ... and how (not yet what) to automate.